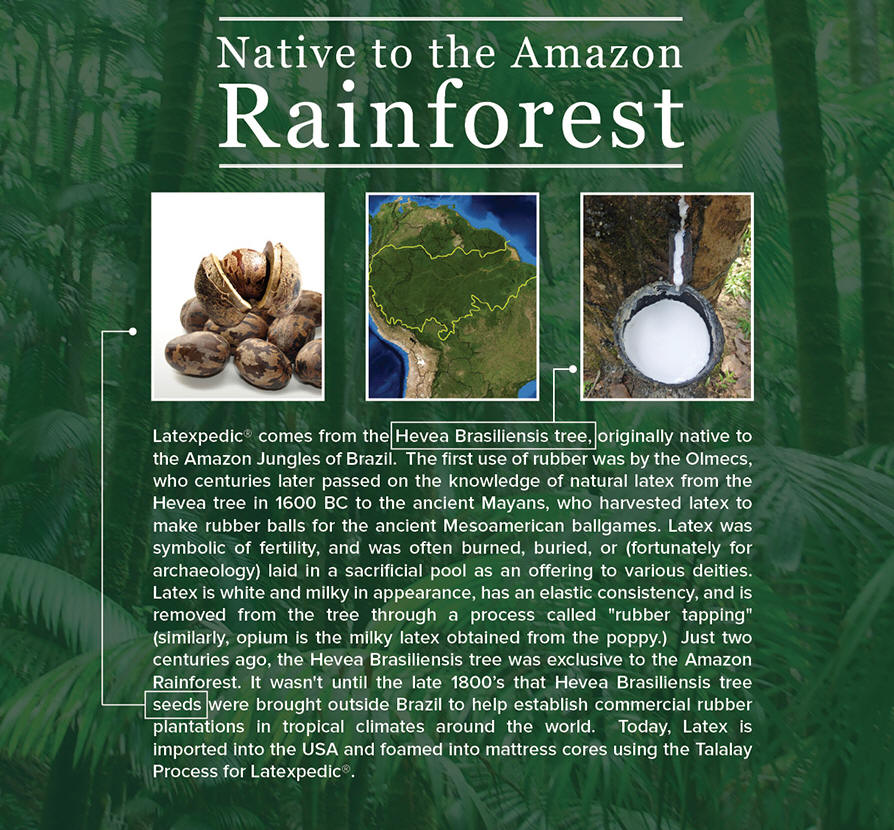

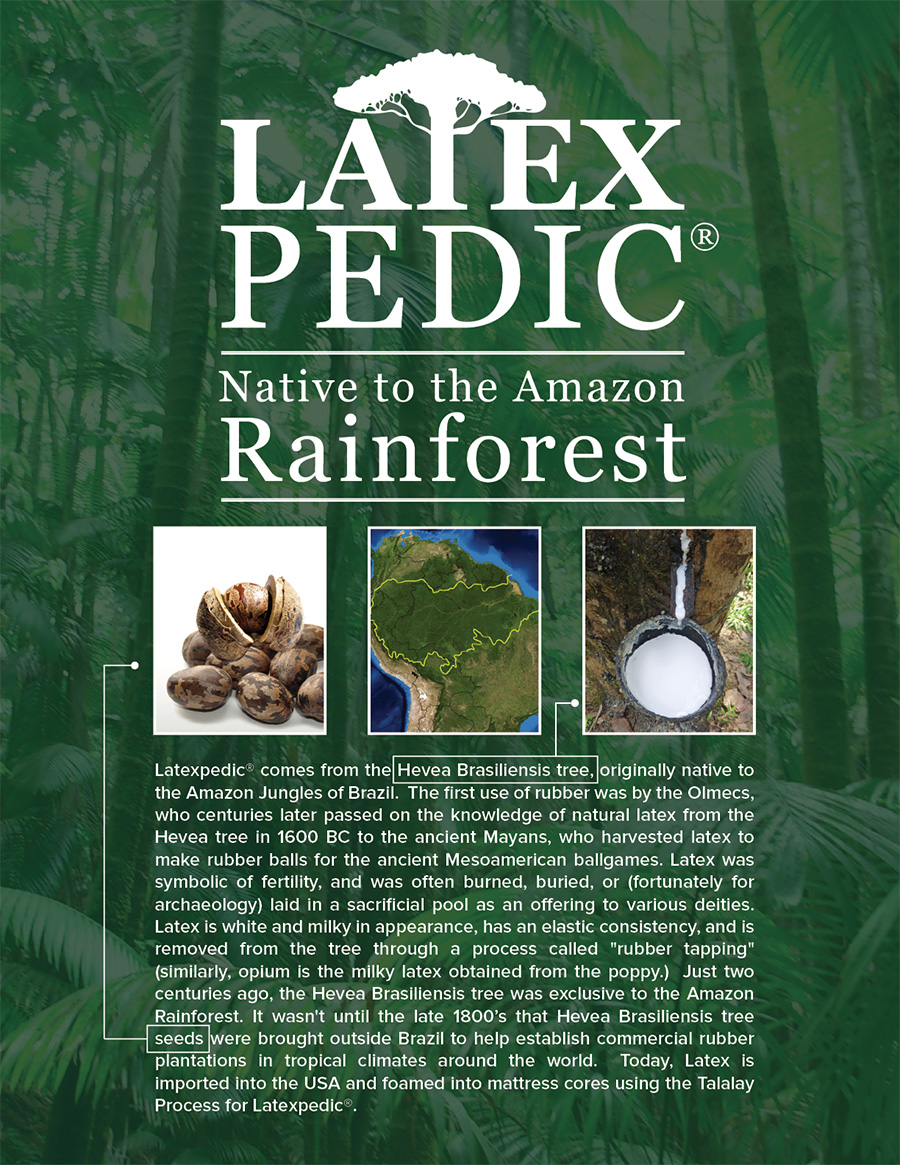

Originally Native to the Amazon Rainforest

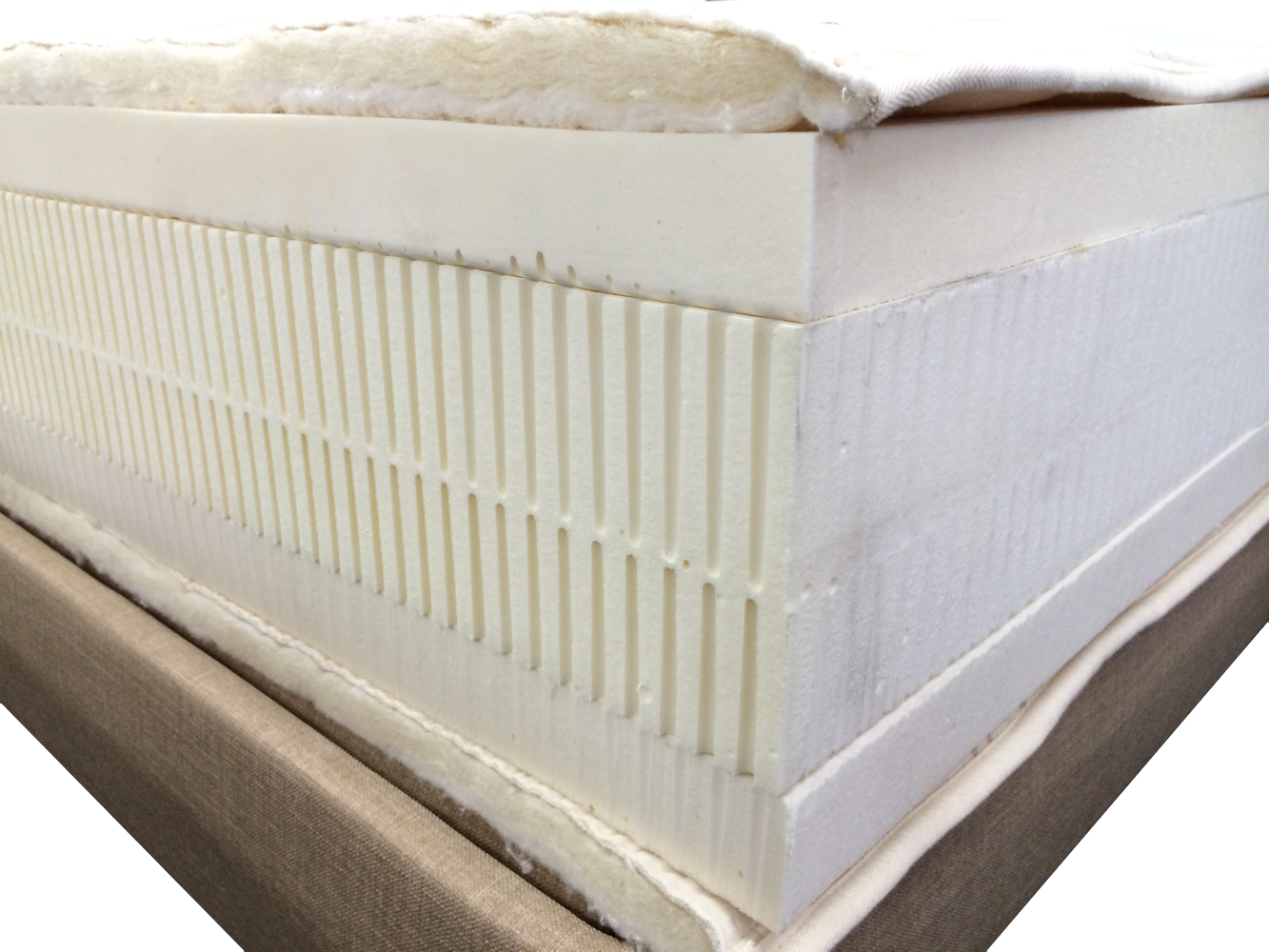

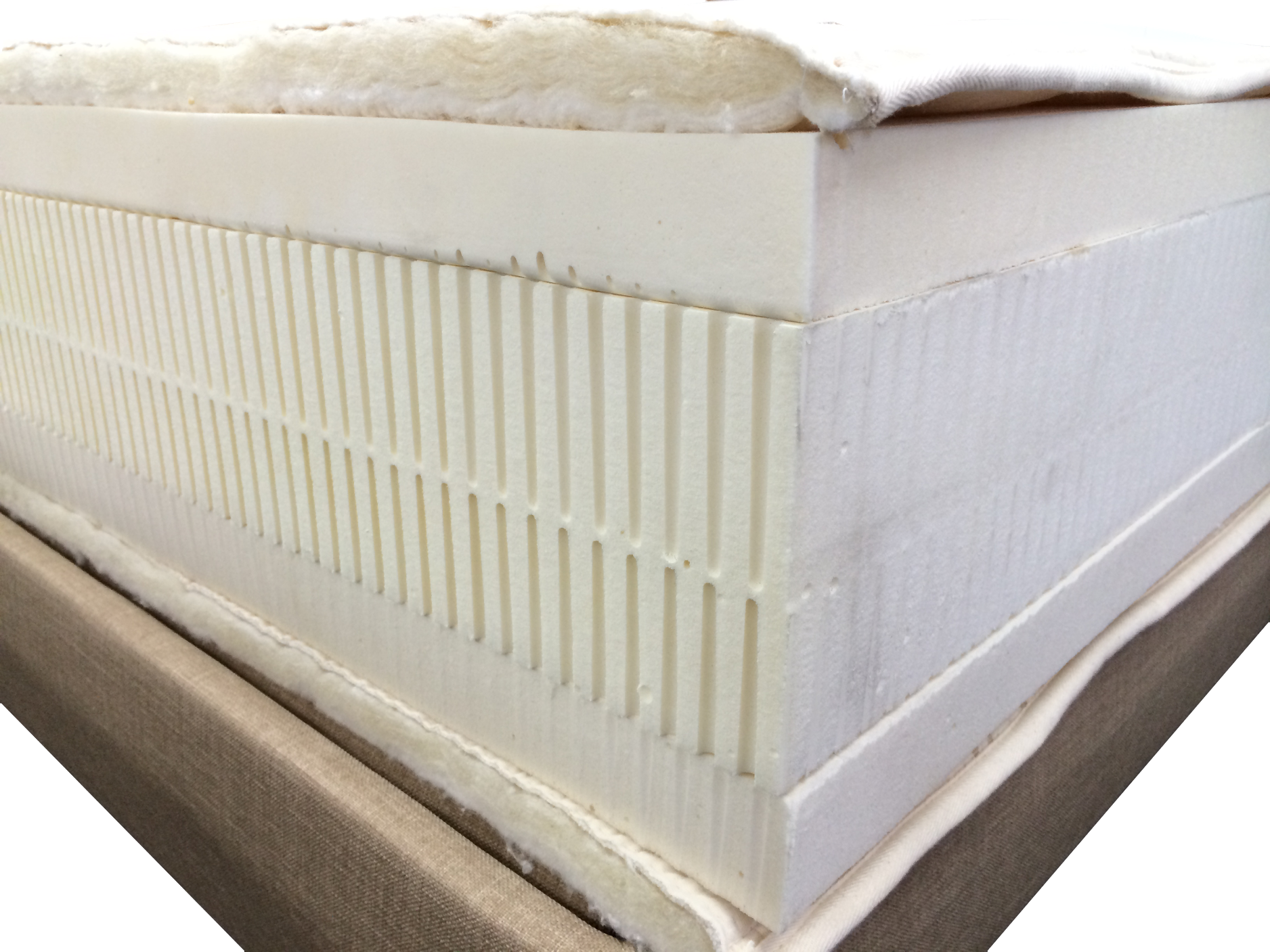

Talalay Latex is the premier material in bedding. Our Talalay delivers a unique buoyant quality which relaxes muscles and relieves tension, lifting away the pressures of the day while you sleep. Careful attention to detail at every step makes certain this amazing feel comes through in the finished product.

What is Natural Latex?

Quality

Talalay vs. Dunlop

Not all latex is created equal. Talalay and Dunlop are the two processes used in mattress production. The Dunlop process was developed in 1929 and was the first method used to produce latex material for bedding.

As technology progressed, the Talalay process was developed by the Talalay family during World War II. The Talalay process is significantly more complex and costly, but produces softer, more buoyant and luxurious finished products.

So why is there such a difference? The Talalay process takes four times longer than Dunlop with two additional process steps—vacuum and flash freezing—which improve the consistency, quality and feel of the finished latex.

The vacuum evenly distributes the latex throughout the mold, allowing us to create precise and varied feels in the finished Talalay latex. A mattress is made more firm or plush based on how much latex is poured into the mold. With the Dunlop process there is little ability to vary the feel of the finished product because the liquid latex is poured onto a conveyor belt resulting in a dense piece of latex every time. The only way to soften the feel of Dunlop latex is to add “fillers” into the liquid latex formula, which can result in solid latex that is flaky and breaks down quickly.

The flash freezing step gives Talalay its consistent feel. Liquid latex is a suspension of rubber particles in water, like a shaken snow globe. Flash freezing prevents the latex particles from settling to the bottom while gelling into a solid product. This means that the resulting piece of solid Talalay latex has the same consistent feel from top to bottom, and side to side. The Dunlop process doesn’t utilize a freeze step. Therefore, the rubber particles settle to the bottom while the liquid latex is gelling into a solid form, resulting in a variation of feel from top to bottom.

Think of Talalay latex like a chocolate soufflé; although the process is long, the end product is a buoyant, airy, complex delight. Dunlop latex is more like a pound cake; tasty, but dense and flat in comparison.

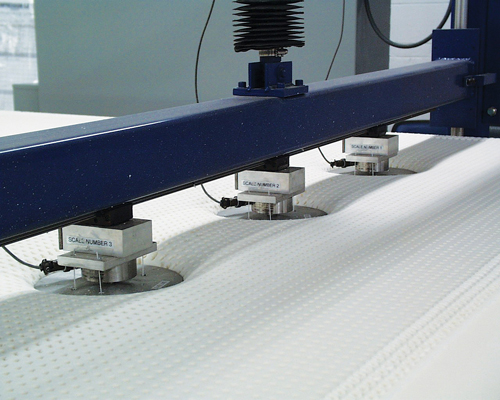

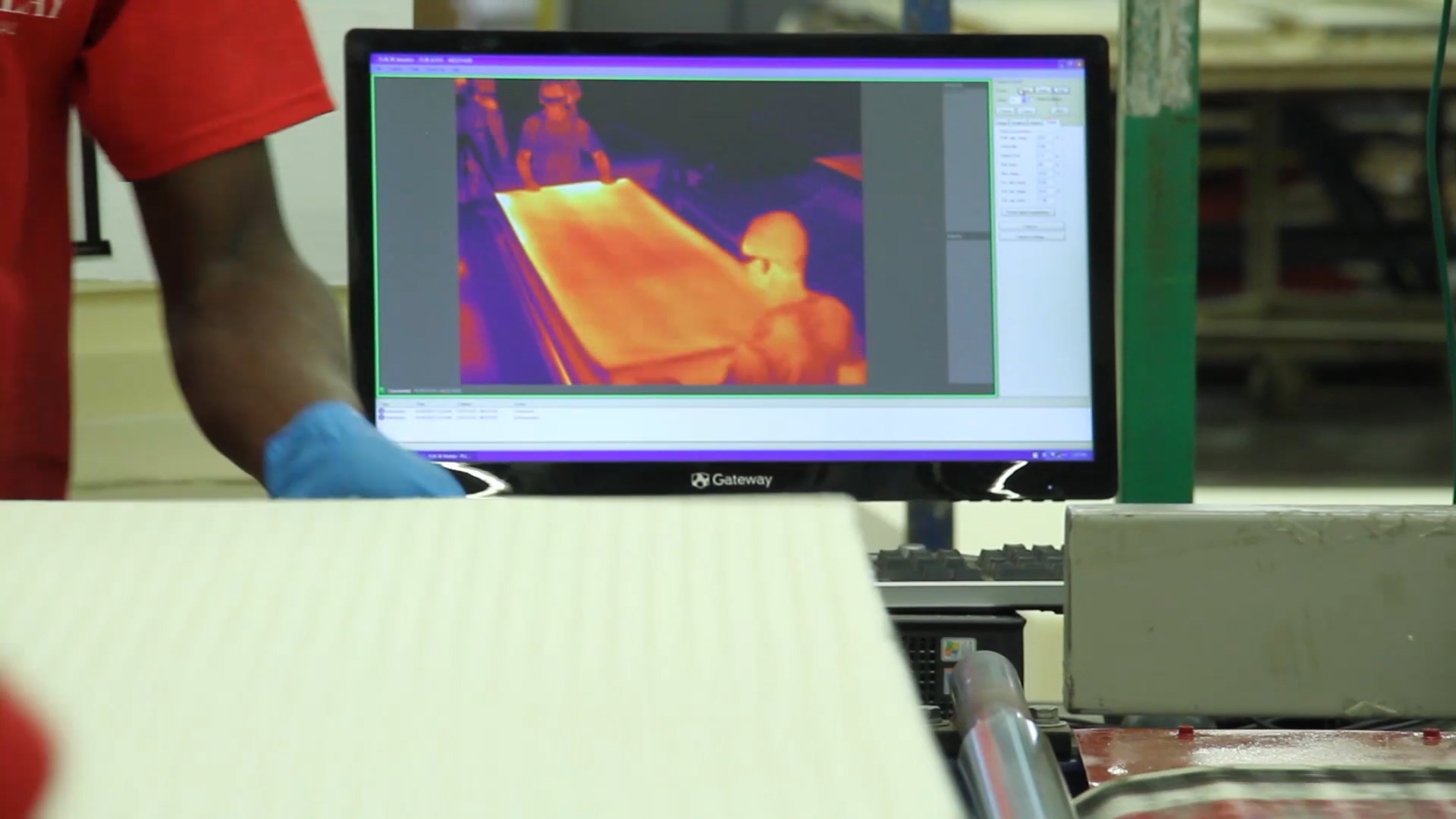

Quality Testing

Only the best pass our tests. Every single bed goes through compression and impact tests to ensure durability and consistency.

Compression Test

This test simulates the effect of body impressions on the latex after a person lies on the bed for extended periods of time. Latex mattress samples are compressed to 50% of their original thickness for 22 hours at 158 ° F. When removed, the percent loss in thickness is measured. The greater the loss thickness, the more likely the bed will take a body impression over time—which leaves you sleeping in a hole.

| Talalay Global Latex | Imported European Talalay Latex | Dunlop Latex | |

| % Compressed | 3.3% | 5.7% | 11% |

| Comparison | — | 73% more compressed | 223% more compressed |

Impact Test

The impact test measures Indentation Load Deflection (ILD), a measure of firmness. The mattress core is ILD tested and then placed into a machine where a weight is dropped on the latex repeatedly for 24 hours. The product is then removed from the machine and allowed to recover for 24 hours. ILD is measured again. The greater the loss in firmness from first measurement to the second means the latex is more likely to breakdown over time. To ensure we produce the most consistent feeling products, Talalay Global ILD tests nine locations on every mattress core. We are the only manufacturer in the industry to do so.

| Talalay Global Latex | Imported European Talalay Latex | Dunlop Latex | |

| % Loss of Firmness | 6% | 16% | 18% |

| Comparison | — | 167% more loss | 200% more loss |

The Talalay Advantage

Do you know what’s inside your mattress? When you have a Talalay latex mattress, the answer is simple; 100% Talalay latex. Every Talalay latex mattress starts out as a tree. We harvest the liquid latex from the tropical Hevea brasiliensis tree and turn it into the finest mattresses, using eco-friendly production methods at our manufacturing facility in Shelton, CT.

Talalay latex mattresses are more breathable, resilient and offer

unmatched support and pressure relief; the key elements to getting

the best night’s sleep you have ever had! You never have to

compromise comfort because we offer a full

Invest in quality. Invest in the environment. Choose Talalay.

6 Reasons to Choose Talalay Latex

It’s

Our Talalay latex is

Oeko-Tex certified as Class I, the highest rating possible.

This certification verifies our products are free from harmful

substances and is even safe for babies. Very few latex or foam

producers in the world meet the standards of this independent,

third-party certification. Even our adhesives are water-based

and free of solvents.

It’s Breathable

Mattresses and pillows made of Talalay latex breathe up to seven

times better than other types of latex or foam products,

allowing for cooler sleep. The materials in most mattresses and

pillows don’t allow body heat to dissipate, which can interrupt

your sleep, but Talalay latex has a breathable design and cell

structure that creates a temperature neutral environment.

It’s Hypoallergenic

Talalay latex is ideal for people with allergies and

It’s Environmentally Friendly

The Talalay process features natural, biodegradable ingredients

that come from renewable resources and water-based raw

materials: natural latex, air and water. The rubber trees are

not harmed in the latex harvesting process. In fact, they are

productive for 25 years, absorbing carbon dioxide from the

atmosphere and helping to reduce greenhouse gases. We are also

mindful of our energy and water consumption during the

manufacturing process. Our manufacturing automation optimizes

energy usage for the molding stage and our state of the art

factory features

It’s Made in the USA

Our manufacturing facility is based in Shelton, CT, USA.

It Doesn’t Off-Gas

Talalay doesn’t off-gas like synthetic foam or polyurethane. You

may notice the “new bed smell” of the latex when it first

arrives, but you can rest assured that no harmful chemicals are

being released because Talalay is made of only natural

ingredients.